Erosion of a trademark may not impact the environment, but marketers have noted lexicographical slide of some brand name became a generic label. Kleenex, Band-Aid, Xerox, and Zamboni (yes, another company making ice resurfacing equipment) are all undergoing a transformation, and Honda VTEC, or Variable Timing and lift Electronic Control, teeters on the edge of the name of a variable-valve exchanges with other -timing the system itself-including several variations on the theme.

When Honda started playing around with VTEC in the early 1980s, it sparked an internal combustion revolution that spread to almost every brand. The simplest resulting system employs a time-variable cam phasers, or mechanisms that alter the relationship between the crankshaft and the camshaft (s). Phasers provide a variety of adjustments, but only for the valve timing. VTEC, on the other hand, work in stair-step fashion, alternating between two or more different cam profiles to change the three variables: valve timing, duration, and lift.

Honda joined the world in 2001, adding they are relatively simple cam phasers for VTEC already complex system. Start a sort of trademark erosion control, VTEC Honda has evolved into a family of separate systems include various combinations of the core set of technologies. Here is how they work:

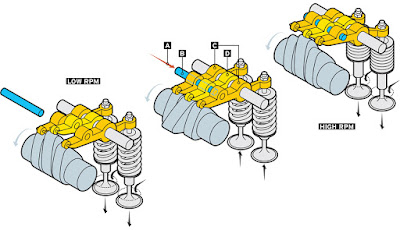

As reva rises, the computer directs the flow of oil (A) through the rocker shaft. This slide pin (B) that locks the lower rpm rocker arm (C) acting on each cylinder two intake valve rocker to high rpm (D). It was the third rocker following a different cam profile is optimized for higher engine speeds. VTEC early operated almost identical to the current basic system.

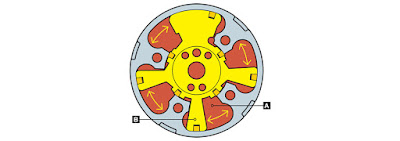

Variable Timing Control is by far the most common form of variable valve timing on the market. Everything from 1.0-liter Fords to many-liter Ferraris use similar camshaft phasers. These devices use oil pressure (A) or an electric motor to advance or retard cam timing (B) relative to crank position

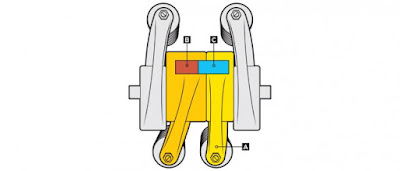

It controls half of the intake valves. At low rpm, only one of the two intake valves operate to promote swirl in the cylinder for efficient combustion and better cold-start emissions are lower. As an expense and an increase in rpm, the second valve (A) moves through the oil pressure (B) against the pin (C).

Variable Cylinder Management deactivate some cylinders when the engine maximum torque is not required. This decouples the cylinder to escape rocker pin (A) is similar to the VTEC pin, so that the rocker (B) no longer opens the valve, effectively sealing the cylinder. Not only does it cut the flow of the mixture into the cylinder die, also reduces pumping losses and friction when activated.

Ultimate VTEC

Engineers have long fantasized about eliminating camshafts altogether. Solenoid-controlled valves could, in theory, have infinite variability without mechanical limitations. A camless engine could run the Atkinson cycle as easily as it could the Otto, have little valve overlap or lots, and run on any or all of its cylinders. But cost, reliability, noise, and other concerns have kept the concept from production. Koenigsegg has a system in the works, and we expect it to be the first to bring it to market—well, the one-percenter’s market, anyway.

Subscribe to:

Post Comments (Atom)

0 Response to "Timing Changes honda's VTEC Variable timming Works system "

Post a Comment